Sai Facility

Our well laid out facility and our state-of-the-art machines endow Sai Paks with the best infrastructure to cater to its customer needs and requirements. We do have a total setup of printing and packaging industry under one roof. A shop-floor area of 25000 sq ft at our works in Chinchwad, Pune with an additional 25,000 sq ft of area at our second facility at Talawde, Pune, houses the entire operations of Sai Paks. With this configuration, we have an efficient facility presenting a convenient one stop shop for our customers to choose services from.

Sai Paks’ latest technology investments are supported by their robust, well established and we’d even say, ‘honed to perfection’ processes. With the leadership’s tremendous focus on doing what it takes to delight their clientele, this documented standardization of processes has resulted in replicable and reliable quality outcomes for customers. And in turn has achieved the ISO 9001 certification for Sai Paks giving a robust and healthy environment for its team to grow and thrive in.

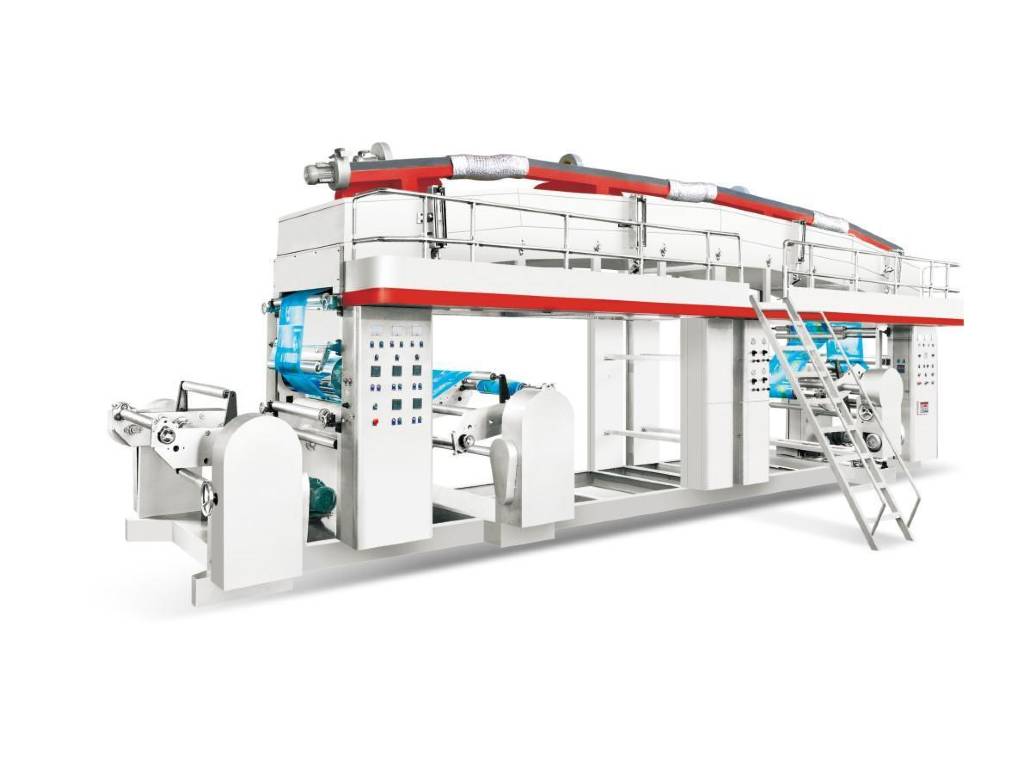

While we unabashedly speak about the diligence and efforts that go into maintaining the company’s up-to-date infrastructure at its best we can only give an indication of some of the highlights of our machines here.

Sai Paks houses several machines for pre-processing, printing and post processing of Cartons and all other publication printing. Automatic Cutting machines, Heidelberg, Shinohara multicolor offset printing press, Automatic Super Folding machine, Perfect Binding U.V coating machines and the newest flexible lamination and 8 color rotogravure printing machines, all significantly automate processes raising the bar for quality and turn-around time to be the best in the industry.

The result? Customers are only delighted by the defect free deliverables at fast speed and optimum price.

Similarly Sai Paks demonstrates its keenness and focus on quality with significant investments in the latest in technology while continuing to nurture age old printing traditions as well. Sai Paks has installed among others multi color printing presses, cold foiling, UV and varnish coating machines, precise die cutting machines, individual label inspections – AVT machine and back numbering for online use.

Sai Processes and Quality Assurance

The ISO certified, standardized and fine tuned process framework is an integral part of our Infrastructure as well. These processes are the basic fabric of Quality Assurance that Sai Paks weaves around every order that they handle for customers.

- The accurate Marketing Message communicating the value authentically and true to the spirit of Sai Paks India.

- The capture and understanding of client requirements, which Sai Paks prides itself upon; this forms the bedrock of a client need well understood and therefore delivered to or exceeding expectations

- In-house design expertise to develop the design

- State-of-the-art machines that enhance flexibility, efficiency, scale, speed and quality are the inherent ingredient of the quality work

- Needless to say… not only operational processes, but even machine maintenance processes contribute to the quality of Sai products

- Complete control on the quality of inputs, including but not limited to the stock, the printing ingredients and the quality of the end product in terms of cutting, pasting, folding and packaging for delivery

- People though mentioned last are definitely not the least important; in fact one of the highest valued contributors to the success of Sai Paks. This key pillar of the business is harnessed, nurtured and well developed with the right training and development built into the company’s processes for on-boarding, development and progression.

In fact nothing but a balanced score board approach is well evident in Sai Paks company’s day to day business which steadily and surely is taking huge strides to continue to rise with its profile, reputation and its standing in the industry.